In the application of precision chillers, flow monitoring is a very important part, sometimes its importance even exceeds temperature monitoring. For the precision chiller of long flow instrument, according to the requirements of users, multi parameter measurement and control system can be selected to measure and control the temperature, pressure, flow, conductivity and other parameters of cooling water, so as to meet the precision cooling requirements of users' equipment.

There are dozens of sensors available for flow monitoring. Among them, the liquid turbine flowmeter is a common precision flow measurement method, which can be used to measure the instantaneous flow and cumulative total amount of liquid together with the corresponding flow integrating instrument. Liquid turbine flowmeter is widely used in the control system of petroleum, chemical industry, metallurgy, scientific research and other fields.

The following describes several types of liquid turbine meters:

A. Field display type

The field display flowmeter is a new flowmeter display instrument designed with advanced single-chip microcomputer technology, which is matched with the flow sensor (such as turbine and vortex) with pulse signal output. Instantaneous flow and cumulative total can be displayed on site.

Signal output: pulse output: 1~3000hz, current output: 4~20ma. External +24vdc power supply, or built-in two 3V lithium batteries for parallel power supply. Under voltage indication occurs when the voltage is lower than 2.7V.

B. Pulse output type

Operating voltage: +12vdc or +24vdc. Signal transmission distance: less than 250m. Output signal: square wave; Signal amplitude: +12vdc power supply amplitude is about 10V, +24vdc power supply amplitude is about 20V.

Installation: amplifier and turbine flow sensor are connected to M16 × 1.5 thread. After the turbine flow sensor is installed, screw the amplifier onto the turbine flow sensor, screw the amplifier to the bottom by hand, and then tighten the locknut.

Wiring: the pulse output amplifier has three external leads, red, white and shielded. The red line is connected to the positive power supply, the white line is pulse output connected to other displays or equipment, and the shield line is grounded.

C. Current 4 ~ 20mA output type

Working voltage: external supply +24vdc (two-wire system) output signal: 4~20ma or 1-5V. 4mA corresponds to the zero flow of turbine flow sensor, and 20mA corresponds to the maximum flow of turbine flow sensor. Signal transmission distance: less than 250m.

Installation: after the turbine flow sensor is installed, screw the amplifier to the connector of the turbine flow sensor and tighten the lock nut after the amplifier has reached the bottom.

Wiring: the external leads of 4~20ma output amplifier are red and white. The red line is the power line and the white line is the signal line.

D. Split remote transmission display type

Working voltage: external supply +24vdc, signal transmission distance: less than 250m. Display instantaneous flow and cumulative total, with 4~20ma output.

The above pulse output signal, current 4-20mA output signal and split remote transmission signal can be connected to the control circuit of the long flow instrument precision chiller for flow display and control.

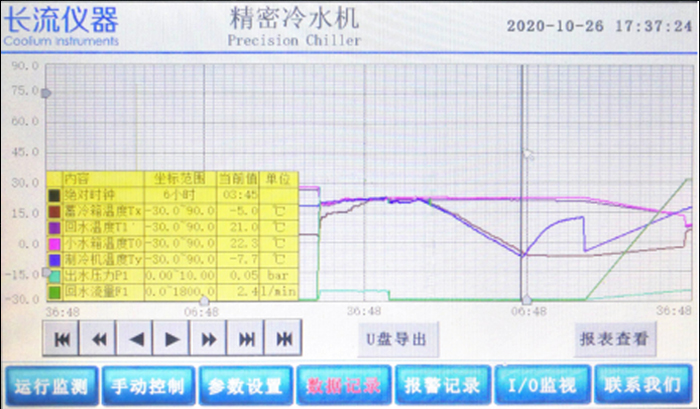

The precision chiller of the long flow instrument also provides a plc+hmi control system, that is, measurement and control parameters such as temperature, pressure, flow and conductivity, which are imported into the touch screen control software to measure and store each measured value in real time, and can form a data table or data curve to facilitate users' data analysis and historical query.