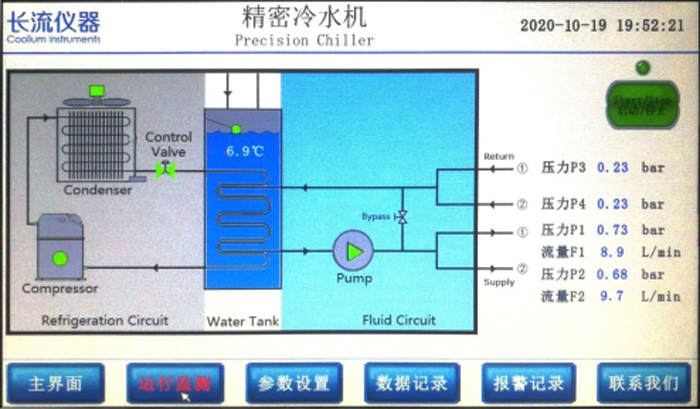

The chiller cools and controls the temperature of the circulating medium in the chiller through the compressor, and sends it to the user's equipment through the circulating pump to take away the heat generated by the user's equipment.

The chiller has three functions of cooling, constant temperature and circulation, and is equipped with a variety of safety alarm devices.

In terms of heat dissipation mode of the whole machine, it is divided into air-cooled chiller and water-cooled chiller.

In terms of temperature control range, it is divided into normal temperature chiller, low-temperature chiller and high-temperature chiller.

The normal temperature is generally controlled within the range of 5~35 ℃, the high-temperature chiller is generally controlled within the range of 5~85 ℃, and the low-temperature chiller is generally controlled within the range of -20~-35 ℃. The long flow instrument can also provide full temperature zone cooling units, high and low temperature circulating units with a temperature range of -20~95 ℃ or -90~180 ℃.

7 technical requirements for chiller type selection:

(1) Temperature control accuracy: temperature control accuracy of cooling water, such as ± 0.1 ℃ and ± 0.01 ℃;

(2) Temperature control range: the temperature range of cooling water, usually 5~35 ℃;

(3) Refrigerating capacity: heating capacity corresponding to user load, generally +30% on the basis of calculated theoretical value;

(4) Circulating pressure: refers to the pressure of cold water delivery, which is closely related to the cooling water flow of user equipment, generally less than 4bar, and the high-pressure type can reach 8~10bar;

(5) Circulating flow: cooling water flow required by user equipment;

(6) Water tank capacity: generally recommended to be greater than the internal capacity of user equipment;

(7) Others: including pipeline material requirements, power requirements, data recording, signal output, alarm and interlock protection, etc.

7 suggestions for chiller type selection:

The chiller is a kind of chiller that assembles all or part of the refrigeration equipment into a whole and directly provides users with the required cold water.

There are many types of chillers, and different chillers are suitable for different environments and uses. The following are 7 suggestions for chiller type selection given by long flow instrument:

1. When selecting the electric driven chiller, when the refrigerating capacity of the chiller is q>1163kw, the centrifugal chiller should be selected; when q=580-1163kw, the centrifugal or screw chiller should be selected; when q<580kw, the piston chiller or scroll multi connected chiller should be selected.

2. The cop (energy efficiency ratio) of the refrigeration system of the electric driven refrigerator is about three times higher than that of the thermodynamic system of the absorption refrigerator. The order of power consumption from low to high is: centrifugal type, screw type, piston type and absorption type. Therefore, only when there is a suitable heat source, especially in places where waste heat or waste heat can be used, or in places where power is scarce, it is appropriate to choose an absorption refrigerator.

3. Generally, 2-4 refrigeration units should be selected, 2 for small and medium-sized units, 3 for large units and 4 for extra large units. The possibility of mutual standby and rotation shall be considered between units. The combination scheme of units with different capacities can be adopted to save energy consumption.

4. Environmental pollution shall be considered when selecting the refrigerator: first, noise and vibration shall meet the requirements of the surrounding environment; second, the harm degree of refrigerant CFCs to the atmospheric ozone layer and the magnitude of the greenhouse effect, and special attention shall be paid to the prohibition schedule of CFCs.

6. For the selection of the number of chillers, single chiller should be avoided as far as possible. If conditions permit, two or more chillers can be selected. In this way, standby units can not be considered. In addition, in case of load change, some chillers can be shut down to save operation costs and make the units operate at a higher COP value.

6. For the cold source of large-scale centralized cooling system, the chiller with compact structure, small floor area and compressor, circulating pump, condenser, evaporator and automatic control components all assembled on the same frame should be selected. For small cooling systems, direct evaporative compressor condensing units can be used.

7. Domestic units shall be selected as far as possible. China's refrigeration equipment industry has developed rapidly in recent ten years. The performance of most products has approached the international advanced level, especially the small and medium-sized chillers, which can be comparable with imported products, and have incomparable advantages in price and service. Therefore, under the same conditions, domestic water chillers should be preferred.