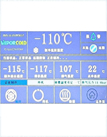

Working Temperature:-145~-90°C

Maximum Load:300~3500W

Pumping Speed:24000~298000L/sec

Professional control panel,RS485 available

Strength guarantee: 25 years of manufacturing experience,

24-hour after-sales service

Online Consultation

For the best films and fastest pumping times, it is critical to remove water vapor from the process environment. The VaporCold closed-cycle Cryochillers provide efficient water vapor pumping with lower total operating costs than liquid nitrogen. VaporCold offers cryochillers in a number of sizes and capacities, with single and dual channel models available.

VaporCold offers cryochiller Coil and Meissner trap design and configuration services. Contact VaporCold Sales for design support.

VaporCold cryochillers provide efficient closed-loop cryogenic refrigeration for water vapor pumping with cooling capacities from 500W to 4200W. VaporCold cryochillers support full system integration and RS485 communications.Optional Ethernet interfaces are available. The PLC+HMI control system will meet your remote operation needs and supports complete data-logging. Analog system control is also available. The touch panel allow rapid scrolling through all available monitor points. Likewise, all available monitor points can be sent remotely to a deposition controller for automated operation.

| Model | Working Temperature (°C) |

Maximum Load (W@-100℃) |

Pumping Speed (L/sec) |

Cryocoil Surface (m²) |

Cryocoil Tube O.D. (mm) |

Cryocoil Tube Length (m) |

Precooling Time (min) |

Defrost Time (min ) |

Dimensions W×D×H (mm) |

|---|---|---|---|---|---|---|---|---|---|

| VPC-500 | -90~-135 | 500 | 24000 | 0.2 | Φ12 | 6 | ≤30 | N/A | 500X550x1200 |

| VPC-1200 | -100~-145 | 1200 | 74000 | 0.5 | Φ12 | 14 | ≤30 | ≤4 | 650X800x1590 |

| VPC-1800 | -100~-145 | 1800 | 104000 | 1.0 | Φ16 | 20 | ≤30 | ≤4 | 650X820x1590 |

| VPC-3500 | -100~-145 | 3500 | 250000 | 2.0 | Φ16 | 40 | ≤40 | ≤4 | 750X920x1650 |

| VPC-5000 | -100~-145 | 5000 | 350000 | 3.0 | Φ16 | 60 | ≤40 | ≤4 | 880×950×1820 |

Optimum design of refrigeration system, efficient and reliable, synchronized with international multistage auto-cascaded technology, refrigeration and defrosting integration.

Perfect control system designed for low temperature. Functions include: self-test, monitoring, remote control, this control, communication, alarm.

The temperature and pressure of 5~8 channels are fully monitored and recorded, and the historical data can be downloaded and queried.

The valve box is arranged at the front of the machine, which is safe and convenient without climbing; Effectively manage the condensate in the valve box to avoid deterioration of refrigeration performance.

Main features of VaporCold water vapor cryochiller:

* Rapid water vapor trapping, shorten the vacuum pumpdown time by 25-90%;

* Improve coating quality, for the best films, better adhesion and more reproducible deposition;

* Fast cooling, cool to -100℃ within 3 minutes, with a minimum of -150℃;

* Fast defrosting, defrost to 20℃ within 3 minutes ;

* The refrigeration system is optimized to cool down again within 3 minutes;

* With industrial PLC and touch panel, Process data logging is supported;

* International brand refrigeration compressor, environmental friendly refrigerant blend;

* International standard refrigeration port, which can be designed as single or two-way load outputs;

* Display and logging of inlet temperature and outlet temperature of single or two-way load;

* Display and logging of internal temperature, water cooling temperature,discharge temperature and discharge pressure;

* The defrosting temperature can be set freely, and will be prompted automatically after defrosting;

* Alarm protection for high discharge temperature and pressure;

* Alarm protection for insufficient water cooling and high water temperature;

* The valve box is placed in front,convenient for operation;

* Local mode and remote mode, convenient for combination control;

* RS485 communication interface to facilitate connection to upper computer.

* Small Footprint

* Attain Deeper Vacuum

* Fast Cool Down for shorter cycle times

* Decrease Pump down Times by 25% to 90%

* More Efficient Water Vapor Pumping

* Fast Defrost and fast cool down again

* Improve Coating Quality and Quantity of products

* Eliminate Costly LN2 Usage For Fast Payback