Ice is a kind of crystalline substance, the latent heat of phase transition is large, the latent heat of ice is 80kcar/kg=335kJ/kg, the ice constantly absorbs heat in the melting process, the temperature remains the same. Compared with other cooling methods, the low temperature cooling of ice mainly uses the latent heat of ice to keep the sample at about 0 degrees Celsius, so that the sample is in a good low temperature state.

The raw material of ice making machine is water. It is a kind of mechanical equipment that generates ice after the water is cooled through the refrigeration system. Broadly speaking, it is a kind of machine that changes liquid water into solid ice. The shape of ice can be divided into many kinds: block ice, cube ice, tube ice, chip ice, snowflake ice, ball ice, etc. No matter what kind of ice it is, its properties determine its use.

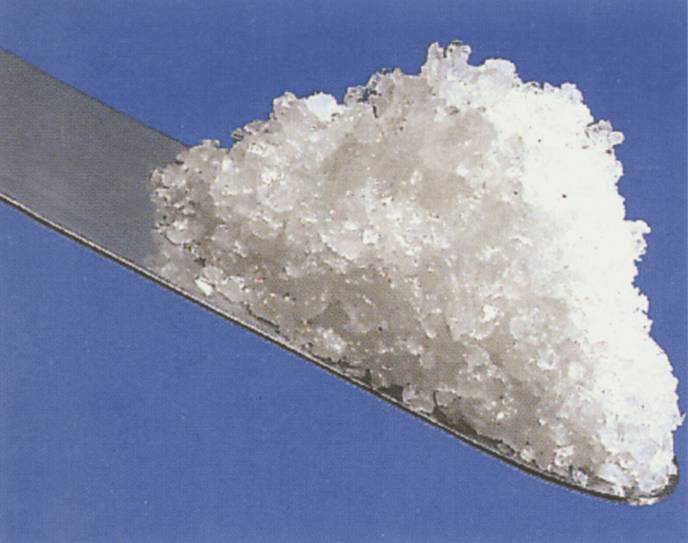

The ice made by the flake ice machine is in the shape of small particles, called snowflake ice, or flake ice for short. It is transparent in shape, not easy to melt, with long storage time, good air permeability, relatively wet in shape, the water content is generally between 15% and 25%, the temperature is slightly below zero, and it is easy to use. The ice is in the shape of small particles, which can penetrate into a narrow gap and cool quickly. Ice bath effect is good, specially designed for laboratory, especially suitable for life science and medicine, food, agriculture laboratories.

Flake ice has a large contact area with the sample and can quickly absorb heat from the sample, reducing the temperature of the sample to about 0 degrees Celsius, and maintaining the temperature range during storage and transportation. In this temperature environment, it can effectively prevent the growth of bacteria, reduce the metabolism of the sample, and extend the life of the sample.

Advantages of flake ice :

1, flake ice temperature is low, can be maintained at 0 degrees Celsius for a long time.

2, flake ice transparent and clean, , not easy to forming large chunks, easy to use.

3, granular structure, large contact area with the sample, good cooling effect.

4, flake ice without sharp edges and corners, will not damage the surface of the sample, iIt's good for storage and transportation.

5, the thickness of the ice is about 1.5~2.5mm, melting slowly, can be used at any time.

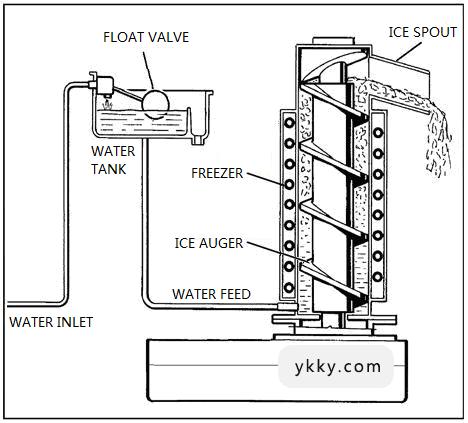

Principle of ice making

Flake ice machine, the water through the automatic control water level of the water tank, into the ice making evaporator, cooled by the refrigeration system to generate ice-water mixture, through the evaporator inside the double spiral ice auger reverse rotation transmission and extrusion, so that the ice water automatically separated, after the subcooling, with the rotation angle constantly changing, extrusion force constantly increasing, the shape of the ice is more irregular. thinner and more crushed, resulting in flake ice with lower water content from the ice outlet.

Flake ice have a unique way of making ice. They utilize a round cylinder evaporator with a double spiral ice auger inside of it that is turned by a high-torque gear motor. The auger sits directly in the center of the evaporator with less than 1/16th of an inch clearance on either side. The auger is always spinning, and it has the shape of a corkscrew. The machine will have a water tank that supplies water to the evaporator whenever it gets low. The machine will start to freeze the water, and as it becomes ice, the continually turning auger will force the ice up to the top of the evaporator and out of a nozzle that will shape the ice into the desired style (crushed or flaked). It is important to notice that with this style of ice machine, the harvest cycle happens when the ice gets thick enough for the auger to scrape it off; it both freezes and harvests the ice at the same time.

The double spiral ice making method overcomes the disadvantage of continuously discharging low-temperature waste water in the ice making process, saves water resources and electric energy, fully utilizes the cold capacity of the evaporator, and improves the amount of ice produced by the ice maker per unit time. Therefore, double spiral ice making is an advanced energy saving and environmental protection scheme.

The above is a brief introduction to the ice making principle of the flake ice machine.

Advantages of flake ice machine:

Flake ice machine is a kind of ice machine, making ice efficient, safe and durable, energy saving and environmental protection, easy to install.

1, high ice making efficiency, small loss of cold

Flake ice machine of Coolium Instruments utilize professional vertical double spiral ice auger evaporator. When making ice, the water inside the ice bucket quickly freezes on the inner wall of the ice bucket. After forming ice, the water is transferred and extruded by the spiral ice auger, so that the surface of the evaporator is fully utilized, which improves the efficiency of the ice maker and reduces the cost of making ice.

2. energy saving, electricity saving, water saving and environmental protection

The cold capacity of the evaporator of the flake ice maker is all used for ice making. There is no need for hot gas fluorine deicing, no deicing process, and it saves energy and electricity. The unique water tank floating ball water intake system can freeze quickly on the inner wall of the ice bucket, realizing the automatic separation of ice and water, no water loss, no residual water, water saving and environmental protection.

3, automatic control, stable performance

Microcomputer chip automatic control, ice full stop, after taking ice automatically resume ice making. Automatically respond to abnormal situations such as water shortage, power failure and refrigerant shortage. Cooling system optimization design, forced air cooling heat dissipation; The refrigerator adopts polyurethane foam insulation for long storage time.

4, simple structure, complete model

Flake ice machine models are complete, the daily ice production rom 40kg/24h~260kg/24h and other specifications. The user can choose the suitable model according to the use occasion and the amount of ice. Compared with the traditional ice machine, it covers a small area and has low operating cost.

5, safe and durable, water and electricity separation

The safe design layout of water and electricity separation is adopted to avoid the safety risks caused by the close distance between the waterway and the electricity circuit. After the power on, self-test is delayed, it automatically enters the working state without manual operation. If there is a fault during operation, the corresponding alarm indicator light will shine, and the corresponding protection measures will start until the machine stops.

6, compact structure, easy to use.

Flake ice machine is compact and easy to get ice. Water inlet and drainage design is reasonable, requiring little countertop or floor space. Small size, light weight, convenient transportation and installation. Can choose the embedded installation model (front air in & front air out), easy to be installed under the experimental table or operating table, or with the overall design of the experimental table, reduce the space occupation of the laboratory.

7, temporary power failure, water shortage solution: in the normal operation of the flake ice machine, even if the sudden power failure, water cut off is no harm. After the water and electricity are restored, the ice maker will automatically resume making ice from the interrupted working state.

8, only need simple water and electricity supply, can ensure the uninterrupted supply of fllake ice.

FM series flake ice machine of Coolium Instruments utilize professional design and manufacturing, excellent quality control and continuous innovation in application. With high efficiency fluorine-free compressor, good refrigeration effect, low noise; stainless steel case, anticorrosive and durable; Integrated structure, save space; Beautiful appearance, reliable performance, representing the perfect combination of quality and performance.

FM series flake ice machine, very suitable for hospitals, schools, research institutes, biological laboratories. The cooling speed is fast and the ice bath effect is good. The low temperature ice bath environment is provided for the samples to prevent the degradation or deterioration of the samples (such as nucleic acid and protein) due to the temperature change, so as to ensure the accuracy and effectiveness of the experimental results.

FM series flake ice machine 24-hour ice production capacity: 40kg, 50kg, 70kg, 100kg, 130kg, 180kg, 220kg, 260kg, users can choose the suitable model according to the use occasion, ice demand.

A simple water and electrical connection is all you need to have a high-quality ice production.