During the coating process with oil diffusion pumps and turbo molecular pumps, more than 80% of the gases remaining in chamber are water vapor, oil vapor, and some high boiling point vapors. This residual gas is difficult to evacuate quickly in high vacuum. the existence of residual gas will not only affect the vacuum degree, but also pollute the production. The water vapor cryogenic trap can effectively shorten the vacuuming time and improve the coating quality.

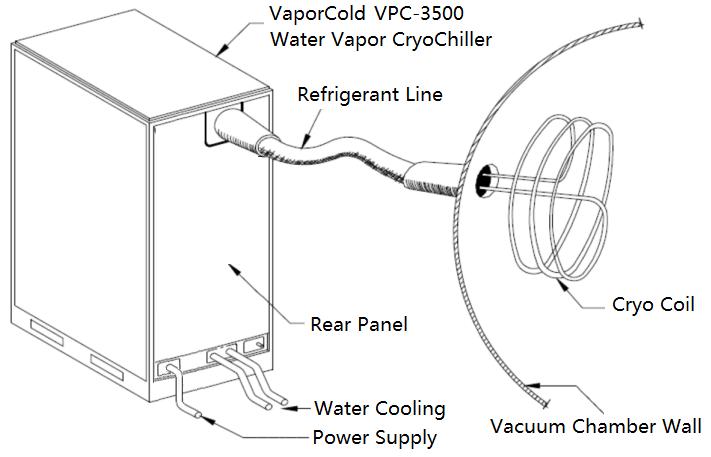

A low-temperature coil (cryo coil) is placed at the vacuum chamber or oil diffusion pump, which can quickly reach below -135℃. The residual gas in the vacuum chamber is rapidly absorbed on its surface through its surface deep-low temperature condensation capacity, thus greatly shortening the vacuum pumping time (can shorten the vacuum pumping time by 60-90%). Obtain a clean vacuum environment (vacuum degree can be improved up to 10^-8 Torr, 10^-5Pa).

1. The cryo coil is usually installed between the high valve and the vacuum chamber, or in the vacuum chamber, in the upper and lower chambers of the winding coating. It is suitable for plastic low temperature coating, winding coating and other coating materials with large ventilation. The coil needs to be heated by the defrosting device to bring the coil temperature back to normal each time before opening the door to prevent the cryo coil from absorbing large amounts of water vapor from the atmosphere, which will affect the next vacuuming cycle.

2, The cryo baffle is placed between the high valve and the oil diffusion pump, under the high valve. Its main function is to prevent oil backflow to the chamber, but also to speed up the pumping speed, increase the vacuum degree. Since the system is in a vacuum, no defrosting device is required.

The VaporCold -135℃ water vapor cryochiller developed and produced by Coolium Instruments has the same performance as Polycold,, with core technology, reliable design, well-known refrigeration compressor and refrigeration accessories, CFC-free refrigerant blend and self-cascade refrigeration, high efficiency, low temperature, easy maintenance. Its design and manufacture are synchronized with the international technical level, and its performance indexes reach or even exceed those Polycod models. It can realize the direct replacement of Polycold.

VaporCold provides complete water vapor cryochiller solutions to help customers improve efficiency, reduce costs, and improve product quality and quantity.