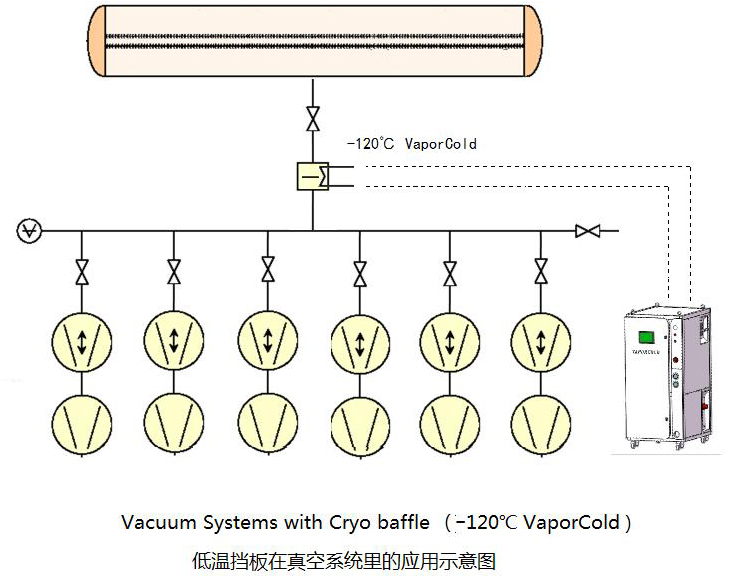

In large vacuum systems, the vacuum acquisition assembly may be composed of many types of vacuum pumps, and must include the front stage vacuum pump with roots pump. The combination of vacuum pumps of different models and sizes is diversified, so that the vacuum degree and pumping capacity can meet the requirements of vacuum process.

In the vacuum system, the condensation and evaporation of condensable vapor will affect the vacuum degree of the vacuum system and the pumping speed performance of the vacuum pump, if the condensation in the vacuum pump may cause damage to the pump. The ultra-low temperature cold trap can effectively capture condensable gas and effectively avoid the above problems.

Cold trap, also called condensate trap, uses ultra-low temperature surface to collect condensable vapor. It is generally installed on the pipeline between the inlet of the main pump and the vacuum chamber, and can effectively collect condensable vapor from the vacuum chamber and the reflux vapor from the vacuum pump. The effect of the cold trap mainly depends on its structure and the temperature of the cold surface used. The larger the area, the lower the temperature, the better the effect.

In vacuum application, in order to achieve good condensation trapping effect, the following aspects should be paid attention to in the selection and design of cold trap:

1、The condensation part should have a large condensation area;

2、The structure prevent straight passage of vapor molecules;

3、Cone tower design, to ensure the maximum flow conductivity;

4、Heat insulation design, as little as possible cold consumption;

5、Easy to clean and disassemble

For example, large space environment simulation equipment, is a very large vacuum system, mainly used for satellite level or spacecraft level spacecraft ground test tests, verification of spacecraft structural design, temperature control design. At present, there are dozens of large space environment simulation equipment in the world, distributed in the United States, Russia, Europe, China, Japan, to meet the needs of large application satellite and manned spacecraft space environment test.

Vacuum environment simulation: vacuum degree 10^-2 ~ 10^-6Pa, including vacuum pump set, vacuum valve, vacuum measuring instrument, gas analysis instrument, etc. Cold black environment simulation: using liquid nitrogen, gas nitrogen system, mixed refrigerant refrigeration, self-cascade refrigeration, etc.

China's large space environment simulation equipment has greatly improved the capability of vacuum test of large spacecraft. The size of vacuum container is very large, such as φ9m×9m, φ10m×12m, φ17m×32m and so on. In terms of vacuum degree, heat sink temperature and automation degree, it has reached or exceeded the level of foreign large-scale space environment simulation equipment, providing a strong guarantee for the core module and experimental module of the space station and the subsequent launch of large spacecraft.

VaporCold series cryochiller with independent intellectual property rights of Coolium Instruments, as vacuum cold trap and low temperature heat sink components, has been used in space environment simulation equipment for many times.

VaporCold series of cryogenic vapor traps adopt the self-cascade refrigeration technology, with a minimum temperature of -150℃. The professionally designed Cryo Coil or Cryo Baffle is widely used in various vacuum systems, and its performance reaches or exceeds that of PolyCold self-cascade refrigeration system.