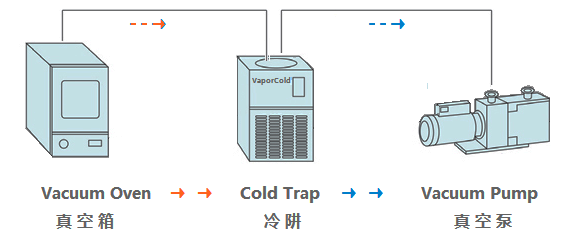

In the process of vacuum drying and vacuum distillation, there will be a large amount of steam, and some solvents or steam need to be recovered. Therefore, it is very necessary to install a low-temperature cold trap on the vacuum pipeline. In addition, the low-temperature cold trap has a great suction effect, which will reduce the drying and distillation time.

The cold trap is placed between the vacuum container and the vacuum pump, that is, before the vacuum pump, so it is called the pre cold trap of the vacuum pump. The low temperature (the lowest temperature of the cold trap can reach -135 ℃) achieved by the compressor of the vaporcold cold trap can make the gas molecules adsorb on the inner wall of the cold trap, improve the vacuum degree and protect the vacuum pump, quickly capture and adsorb water vapor, oil and gas, shorten the pumping time and improve the pumping capacity of the vacuum system.

The front cold trap of the vacuum pump can reach a minimum temperature of -30 ℃ /-50 ℃ /-80 ℃ /-110 ℃ /-135 ℃. Various vacuum interface modes can be selected, and condensing bottles of various specifications can be equipped. The effect of condensation trapping depends on the internal structure of the cold trap, the low temperature surface area and the lowest temperature that the cold trap can reach. Generally speaking, the lower the temperature, the larger the area, and the better the effect.

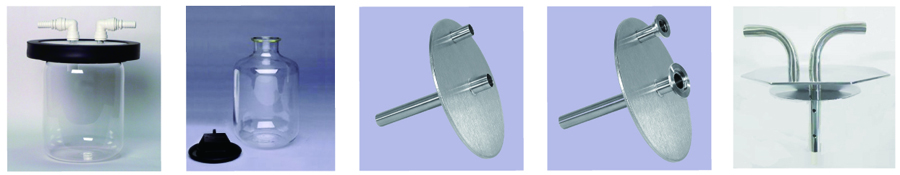

The materials of the parts in contact with the gas inside the cold well shall adapt to the different characteristics of water, acid and organic solvents. It is recommended to use teflon coated cold traps or glass containers to condense corrosive gases or to recover condensed liquids.

Product features:

1. the cold well groove is made of stainless steel and is cooled directly. It is easy to clean the cold well and drain the liquid.

2. the temperature in the cold trap tank is displayed digitally, and the startup and operation status of the cold trap device can be seen at a glance.

3. optional cold trap cover for condensed water vapor or special cold trap cover assembly for organic solvent gas.

4. for acidic and organic solvent vapors, glass condensing bottle can be selected to improve the recovery rate of low boiling point solvent.

5. optional defrosting function to simplify ice melting and drainage. Optional temperature control and constant temperature function to meet special needs.

6. low temperature, fast refrigeration, can be used as pre freezing tank and low temperature tank.

The capacity of vaporcold cold trap can be divided into 2L, 4L, 6L, 9L and 25L. The low temperature can reach -30 ℃, -50 ℃, -80 ℃, -110 ℃, -135 ℃. The main models are ct2-30, ct2-50, ct4-50, ct4-80, ct4-110, ct4-135, ct6-50, ct6-80, ct6-110, ct6-135, ct9-50, ct9-80, ct9-110 and ct9-13.

| Model | Working Temperature (°C) | Maximum Load (W@-100℃) | Pumping Speed (mm) | Dimensions W×D×H (mm) |

|---|---|---|---|---|

| CT2-30 | -30 | 2 | Ф120 * 200 | 250×430×360 |

| CT2-50 | -50 | 2 | Ф120 * 200 | 250×430 ×360 |

| CT2-80 | -80 | 2 | Ф120 * 200 | 300×500× 430 |

| CT4-50 | -50 | 4 | Ф160 * 200 | 360×600×300 |

| CT4-80 | -80 | 4 | Ф160 * 200 | 450× 630×380 |

| CT4-110 | -110 | 4 | Ф160 * 200 | 450×630×380 |

| CT6-100 | -100 | 6 | Ф200 * 220 | 440×520×880 |

| CT6-120 | -120 | 6 | Ф200 * 220 | 440×520×880 |

| CT6-135 | -135 | 6 | Ф200 * 220 | 500×550×1180 |

| CT9-100 | -100 | 9 | Ф220 * 250 | 440×520×880 |

| CT9-120 | -120 | 9 | Ф220 * 250 | 440×520×880 |

| CT9-135 | -135 | 9 | Ф220 * 250 | 500×550×1180 |

Common cold trap models in the market at present: wct-40, wct-80, rvt400, rvt450, rvt4104, rvt5105, ut-500, ut-1000, UT-2000, ut-3000, ut-4000, CA301, ca801, tt4105, tt8105, vt255, vt455, vt490, vt890, ct-2000, ct-5000, jm50, jm80, va-120, va-140s, va-250f, va-500r, va-800r, etc.