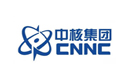

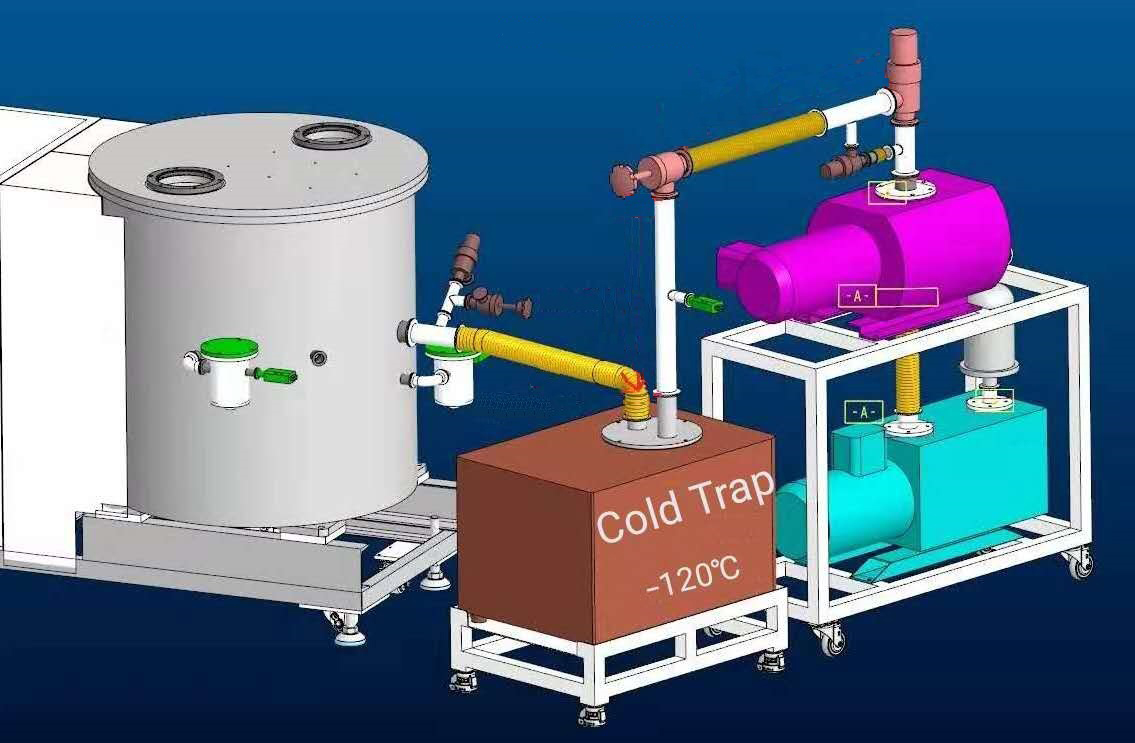

On parylene vacuum coating equipment, a low-temperature trap is required between the coating chamber and the vacuum pump. See the following figure.

There are three common low-temperature traps:

1) Liquid nitrogen cold trap is the most economical low-temperature capture method, which is simple, reliable, easy to maintain and low cost. However, the supply of liquid nitrogen is restricted by many factors. In addition, it is not convenient to inject liquid nitrogen into the cold head.

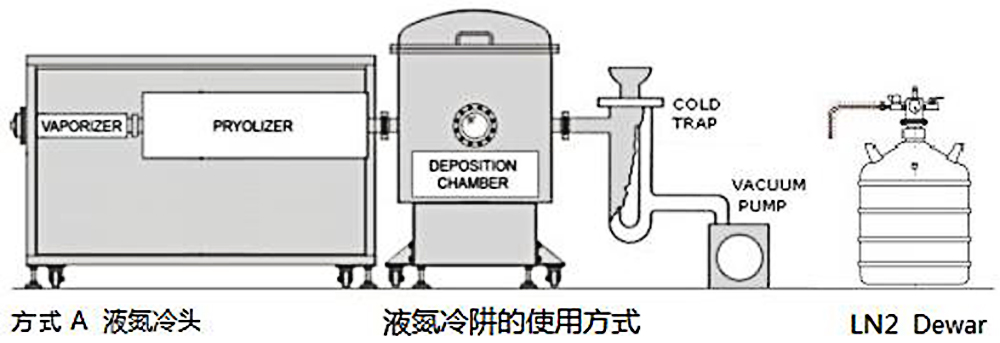

2) The cold head of ultra-low temperature refrigerator, replacing the liquid nitrogen cold trap, is the most common low-temperature capture method. The advantage is that it can directly replace the liquid nitrogen method, which is easy for users to understand and accept. The disadvantage is that there is a non removable low-temperature hose between the cold head and the refrigerator, which will lose part of the cooling capacity. If the refrigerator is moved at low temperature, it is easy to damage the hose and cause refrigerant leakage. Assembled with vacuum system, it takes up more space.

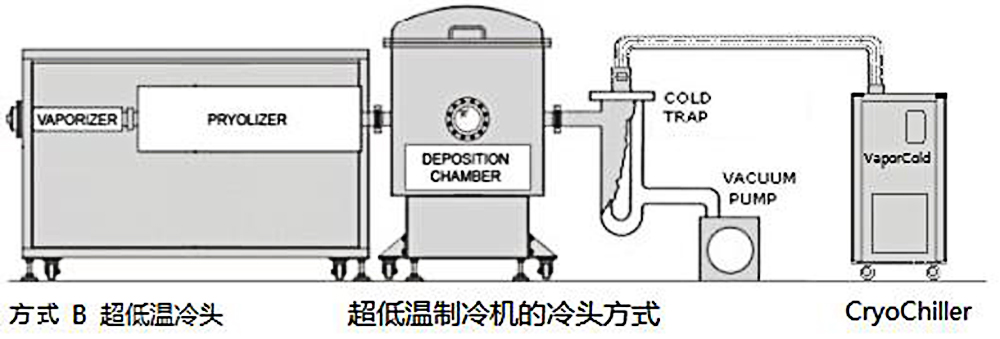

3) It is more reasonable to replace the liquid nitrogen cold trap with the cold trap of ultra-low temperature refrigerator. Remove the liquid nitrogen cold head and the vacuum tank together, and connect the vacuum hose from the vacuum interface of the coating chamber to the vacuum interface of the ultra-low temperature cold well, and then to the vacuum pump. Compared with the ultra-low temperature cold head, the ultra-low temperature cold well is simpler and more reliable, and easier to install and maintain.

As a low-temperature trap, the liquid nitrogen cold head has low capture temperature and simple maintenance, but it is inconvenient to use. It is common in the laboratory.

In the industrial field, it is common to use the ultra-low temperature refrigerator as the low-temperature trap, with the temperature range of -80 ℃ ~-145 ℃, which is generally divided into two ways: cold head and cold trap.

The advantage of the ultra-low temperature cold head is that it directly replaces the liquid nitrogen cold head, and also makes use of the additional vacuum tank of the original liquid nitrogen cold head. The disadvantage is that the liquid nitrogen cold head or ultra-low temperature cold head, and the flange interface is non-standard, which needs to be customized; The black connecting hose of the ultra-low temperature cold head has relatively insufficient insulation layer, which will lose part of the cooling capacity. It is also fragile at low temperature, so it is strictly prohibited to move.

The ultra-low temperature cold trap method does not need additional vacuum tank, and the whole machine mechanism is simple. Directly connect the cold trap from the coating chamber. No loss of cooling capacity, firm and durable; The interface adopts the vacuum standard form kf40 or kf50, which is very convenient and reliable. It is also the conventional design scheme of the vacuum system.

The left side of the figure below shows the way of cold head. The black low-temperature connecting pipe is fragile at low temperature and has cold capacity loss.

The right side of the figure below shows the way of cold trap. The vacuum connection is simple and reliable. The coating chamber is equipped with a cold trap and a vacuum pump.

The large figure below is the design diagram of the bench type cold trap (which has been applied in batches).

In the field of ultra-low temperature, coolant instruments is a leading R & D enterprise, providing customers with a wide range of low-temperature products. For example, standard models with minimum temperatures of -50 ℃, -80 ℃, -110 ℃, -120 ℃, -135 ℃ and -145 ℃. At the same time, it also accepts non-standard customization of various user needs.

It has been more than 15 years since the long flow instrument vaporcold ultra-low temperature cold trap was equipped with parylene equipment, with more than 500 matching ultra-low temperature cold traps. Users are distributed in domestic, Southeast Asia, Europe, North America and other markets.

Changliu instrument serves parylene equipment, has rich experience and confidence, and can provide users with a variety of solutions. The following figure is a picture of some models of long flow instrument, including ultra-low temperature cold head and ultra-low temperature cold trap.

*The single compressor self cascade refrigeration technology has the advantages of fast cooling, low temperature, energy saving, environmental protection and reliable performance.

*There are a wide range of models, vertical or desktop, cold head or cold well, which are convenient for users to choose.

*The cold head or cold well shall be designed, manufactured and tested according to the vacuum standard to meet the vacuum technical requirements.

*On the low-temperature surface of the cold head or cold well, some models can choose anti-corrosion coating, which greatly delays the service life.

Below are some application examples at home and abroad, with different forms of cold traps for comparison and reference: