1. Introduction to cold trap

A cold trap is a device placed between a vacuum container and a vacuum pump to condense, adsorb or capture gas.

Cold trap and low temperature cold trap, as a cooling device, can condense and capture gas molecules whose condensation point temperature is higher than that of the cold trap through the low temperature surface, and can also capture specific gas molecules by setting the condensation temperature, which can play a role in gas separation.

2. Types of cold traps

According to the different cooling methods of the cold trap, the cold trap is generally divided into two types: self-cooling and external cooling.

2-1 self-cooling cold trap

The cold trap is integrated with the refrigerator, and the refrigerator cools the cold trap. The lowest temperature of the self-cooling cold trap is related to the refrigeration capacity of the refrigerator. The cold trap and the refrigerator are integrated into one, and the refrigerator cools the cold trap. The lowest temperature of the self-cooling cold trap is related to the refrigeration capacity of the refrigerator. The low temperature cold trap temperature is generally -30℃ or -50℃, and the ultra-low temperature cold trap can reach -80 or -110℃ below.

Self-cooling cold trap, independent operation, simple operation, easy to use, is the mainstream cold trap scheme. In the field of environmental monitoring and industrial production, the self-cooling cold trap is a reasonable choice due to strict process limitation and aging requirements.

2-2 External cooling type cold trap

The cold trap itself has no cooling capacity, so it needs to rely on external cold source for cooling. It needs to be equipped with low-temperature chiller, dry ice, liquid nitrogen, etc. The cold trap temperature depends on the temperature of the external cold source, such as dry ice acetone, up to -78℃; With liquid nitrogen, up to about -190℃.

Externally cooled cold trap has low cost and flexible configuration. It is a common option for laboratory personnel in vacuum distillation experiment.

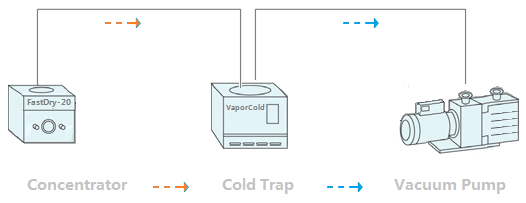

3. The important role of cold trap in vacuum operation

3-1 Increases vacuum efficiency

The oil and gas and water vapor in the vacuum chamber are condensed into liquid or solid state by using the low temperature surface of the cold trap to reduce the influence on the vacuum degree. Taking 1g of ice as an example, 10,000 L of water vapor can be generated at a vacuum of 0.1Torr. The water in the drying box will produce a lot of water vapor. If such water vapor is removed only by vacuum pump, the efficiency of vacuum pump will be reduced. The low temperature of the cold trap can condense water vapor directly in the cold trap, thus greatly improving the working efficiency of the vacuum pump. That's why the drying oven and the centrifuge concentrator are equipped with cold traps.

3-2 Reduce the impact of corrosive gases on vacuum pumps

There are often corrosive reagents in the vacuuming system. Corrosive reagents are converted into gas molecules during vacuumization and discharged into the atmosphere through a vacuum pump and pipeline. Corrosive gases may damage the vacuum pump. For example, acidic gases corrodes the metal components of the vacuum pump. Corrosive gases are directly discharged into the atmosphere through the exhaust port of the vacuum pump, which may also pollute the air.

The cold trap can condense and collect corrosive gases before entering the vacuum pump, reducing the damage of corrosive gases to the vacuum pump. In vacuum operation, rational use of cold trap can increase the efficiency of vacuum pump, prolong the service life of vacuum pump, increase solvent recovery, reduce environmental pollution and so on.

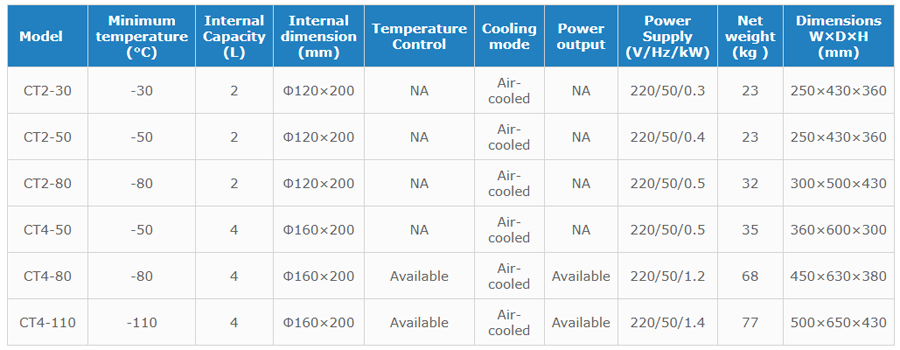

4. VaporCold Cold Trap Introduction

VaporCold is a self-cooling cold trap with an integrated structure that can provide cold trap temperatures of -50 ° C, -80 ° C, -110 ° C and -135 ° C, with optional cold trap volumes of 2L, 4L, 6L, 9L and 25L.

VaporCold series cold trap is a small ultra-low temperature device that uses automatic cascade refrigeration. Suitable for gas condensation and capture, low temperature liquid bath, oil and gas recovery, material testing, drug freeze-drying and other applications. Can be used as low temperature tank, pre - freezing tank, low temperature container. Can provide ultra-low temperature conditions for all kinds of small systems.

The size and interface mode of the cold trap can be customized according to demand. The vacuum sealed cold trap is optional, and a variety of specifications of condensation bottles can be matched. Multiple self-check and safety protection, optional temperature correction, power failure recovery, sensor abnormal alarm, 485 communication and remote control.

In vacuum drying and vacuum distillation process, a large amount of steam will be generated, and some solvents or steam need to be recovered, so it is necessary to install low temperature cold trap in vacuum pipeline. In addition, the low temperature cold trap has great suction effect, which will reduce drying and distillation time.

Ideal for vacuum operation, VaporCold Cold Trap is available in a wide range of sizes and specifications. Welcome to long flow instrument, we will provide you with a variety of vacuum operation, cold trap recommended options.