Parylene (poly paraxylylene) is a generic name for polymers that belong to a unique chemical family and are used as conformal coatings in protective applications. The coating process exposes product to the gas-phase monomer at low pressure. Through vacuum deposition, parylene condenses on the object's surface in a polycrystalline fashion, providing a coating that is truly conformal and pinhole free.

Compared to liquid processes, the effects of gravity and surface tension are negligible, so there is no bridging, thin-out, pinholes, puddling, run-off or sagging. The process takes place at room temperature so there is no thermal or mechanical stress on the product. Parylene is physically stable and chemically inert within its usable temperature range. It provides excellent protection from moisture, salt spray, corrosive vapors, solvents, airborne contaminants and other hostile environments.

Parylene can be applied to almost any substrate that can withstand the vacuum. These materials include stainless steel, plastic, silicon, paper and ceramics to name a few.Parylene coating technology is widely used in aerospace, precious relics, silicone rubber, seals, magnetic materials, MEMS, circuit boards, sensors, biomedical and other fields.

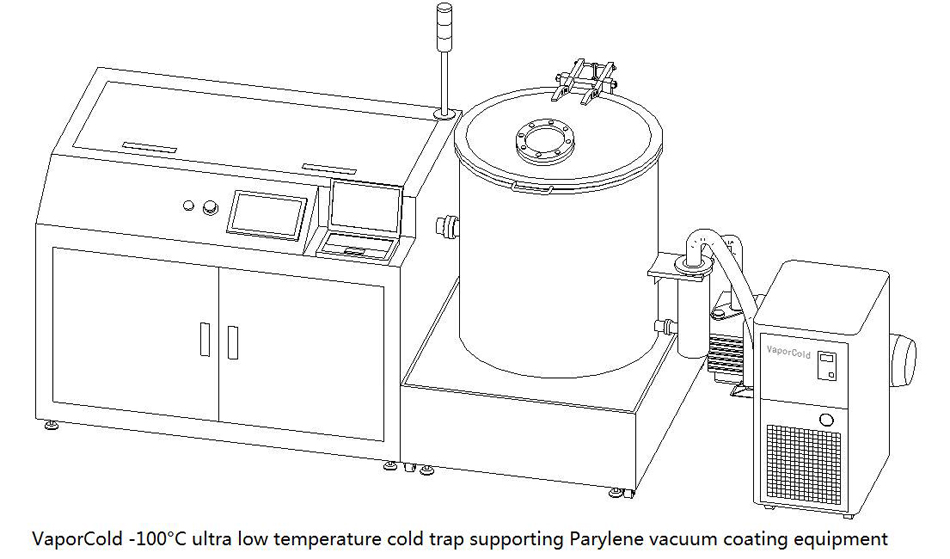

The process begins with raw dimer in solid state being placed into a loading boat, which is then inserted into the vaporizer. The raw dimer is heated between 100-150℃. At this time, the vapor is pulled, under vacuum into the furnace and heated to very high temperatures which allows for sublimation and the splitting of the molecule into a monomer. The monomer gas continues to be drawn by vacuum one molecule at a time onto the desired substrate at ambient temperatures in the coating chamber. The final stage of the parylene deposition process is the cold trap. The cold trap is cooled to between -90℃ and -120℃ and is responsible for removing all residual parylene materials pulled through the coating chamber.

A cold trap is used between the deposition chamber and the vacuum pump. The cold trap prevents parylene molecules that have not deposited in the chamber from getting into the vacuum pump,and prevents oil molecules from "back streaming" into the deposition chamber.

The cold trap can be liquid nitrogen or mechanical refrigeration ultra-low temperature cold trap, the lower the temperature, the more conducive to parylene molecular trapping.

Coolium Instruments has long been committed to developing and producing the cryogenic refrigeration technology, VaporCold series cryogenic refrigerators (cold traps), which is the perfect substitute for PolyCold cryogenic equipment and is used in Parylene vacuum coating equipment. and provides -100℃, -120℃, -135℃ ultra-low temperature cold trap for domestic and foreign vacuum equipment manufacturers.

In the past two decades, VaporCold series -100℃ vacuum coated cold trap, -120℃ ultra-low temperature freezer, -135℃ water vapor cryochiller, -150℃ ultra-low temperature refrigerator and metal cryogenic treatment box, -120℃ to -170℃ ultra-low temperature space simulation unit, We have won the bidding of core projects of Chinese Academy of Sciences, China Academy of Rocket Science and China Academy of Engineering Physics for many times, providing ultra-low temperature equipment ranging from -100℃ to -170℃ for aerospace industry, biopharmaceutical, medical and health care, vacuum coating, photoelectronics, solar energy, metal processing, environmental monitoring and other projects.